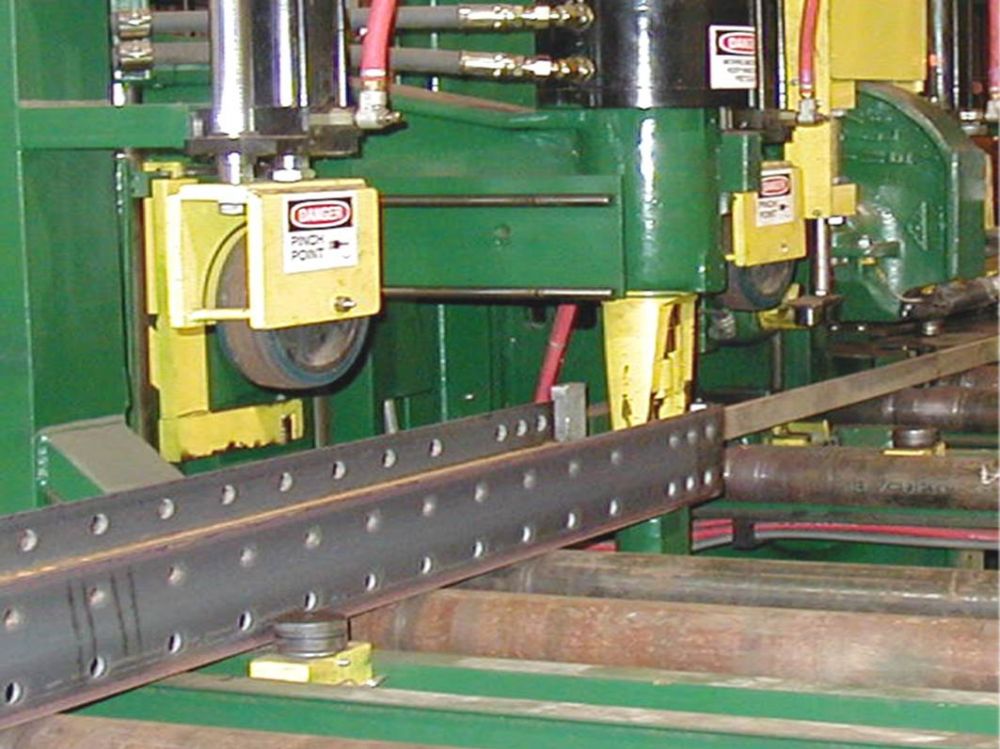

Punching and Shearing

|

|

|

|

Anderson has the experience and expertise to manufacture complete product ranges – from custom “one of a kind” to full production run quantities of your product. Versatile manufacturing equipment and techniques, provide the capability to quickly and economically produce a wide variety of metal fabrications to meet your needs. We belong to:

|

|

| American Institute of Steel Construction |  |

Anderson’s customer base ranges from small businesses to Fortune 500 companies, yet each receives the same attention to detail and outstanding customer care. This customer service, along with quality products, innovation, commitment to excellence and delivery schedules are the qualities that set Anderson Building Materials Company apart from the competition.

Cutting and Punching

Anderson uses state-of-the-art CNC machinery to accurately and economically process large quantities of material. Mill bundle cutting saws, conveyor systems, as well as a beamlines and angleline allow Anderson to quickly and efficiently provide length and hole processing for structural shapes, including:

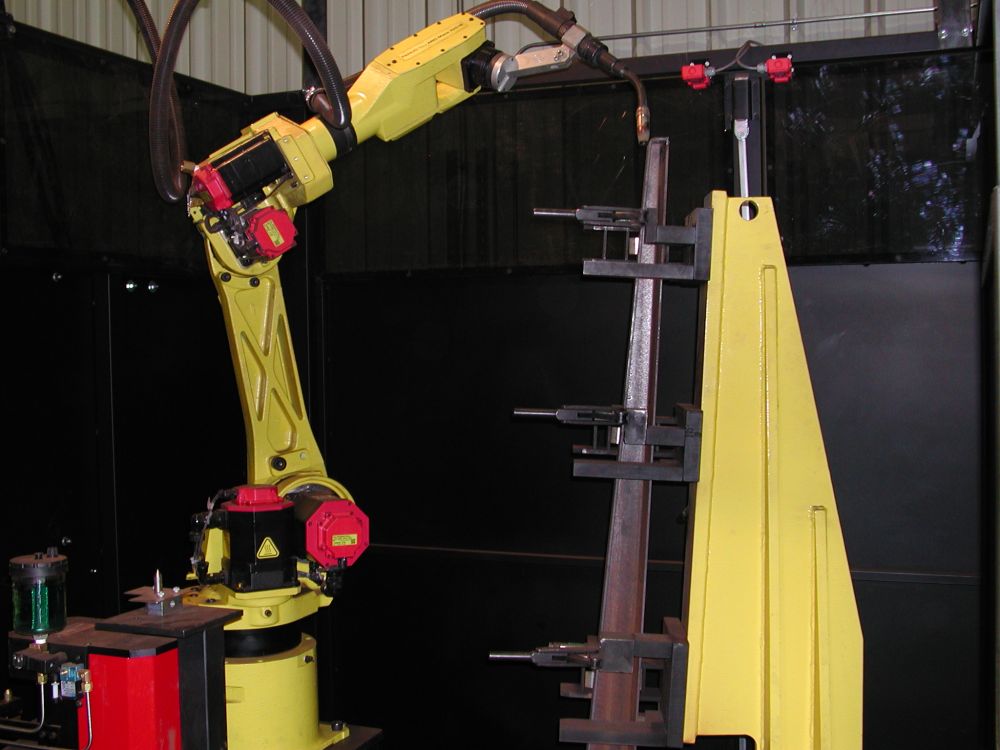

Robotic & Manual MIG Welding

Anderson’s multiple robotic welding cells currently provide production quantities of Cantilever Rack and various other assemblies. With large welding envelopes, quick-turn platforms and accurate fixtures, these systems have the ability to weld a wide variety of shapes, sizes and components on a repetitive quality basis.

Contact us to see how we can apply these efficiencies and cost savings to your products.